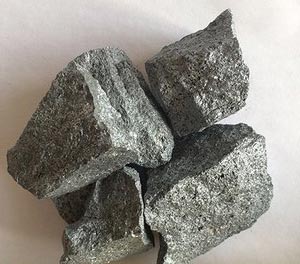

Ferrosilicon ball as a common ferrosilicon products, its advantages are very obvious, in fact, there are many kinds of ferrosilicon products composed of iron and silicon, such as ferrosilicon ball, ferrosilicon grain, ferrosilicon powder, ferrosilicon block, these can be quickly distinguished through the shape. But according to the content of each element in ferrosilicon composition, can also be divided into different brands. However, no matter what kind of ferrosilicon product, it is made from coke, steel chips, quartz (or silica) as raw materials, by electric furnace smelting.

Ferrosilicon products can not only be divided into different types, at the same time, there are many uses of ferrosilicon, and in different fields of application, play different roles. For example, ferrosilicon is often used as a deoxidizer in steel making, and due to the release of a lot of heat when SiO2 is generated, it is also favorable to improve the temperature of molten steel at the same time of deoxidation. At the same time, ferrosilicon can also be used as alloying element additive, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel, ferrosilicon in ferroalloy production and chemical industry, commonly used as reducing agent.

Ferrosilicon ball as one of many ferrosilicon products, compared with other kinds of ferrosilicon products, ferrosilicon ball has uniform particle size, reducing the loss of natural block of ferrosilicon used in steelmaking, labor, electricity and transportation. Uniform particle size, accurate feeding, good deoxidation effect, shorten the deoxidation time, save energy, improve the efficiency of steelmaking, improve quality in addition to low raw and auxiliary material consumption, high recovery rate, reduce labor intensity, melting speed, uniform division, reduce power consumption.